Have you ever wondered how a large academic library keeps the most frequently used books in its collection in good condition? Who takes care of the rare volumes? I got to find out when the head conservator of the Harold B. Lee Library, my friend Christopher McAfee, offered me a behind the scenes tour!A university needs to be confident that when it makes fragile editions available to students and faculty, a competent conservation staff is available to perform repairs and to employ techniques and materials that protect these editions from use and aging. BYU is fortunate to also have a book repair staff that is responsible for maintaining the circulating collection, as well.

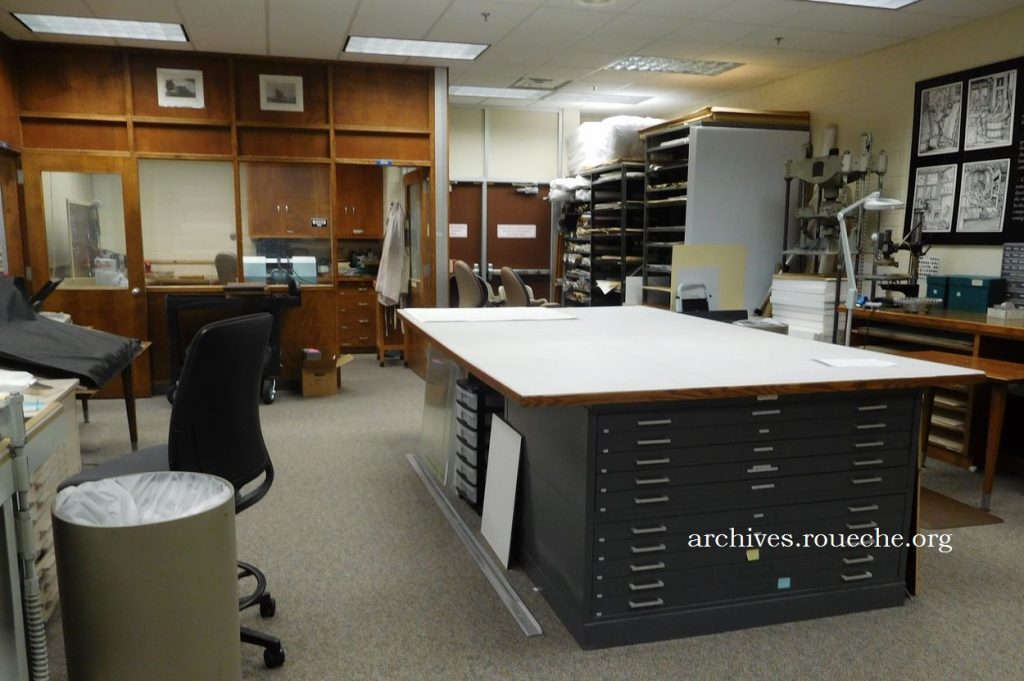

The conservation lab was a light-filled and spacious series of rooms. Let’s begin the tour!

The main space is divided into two rooms.

A clean, open work space for paper storage and cutting.

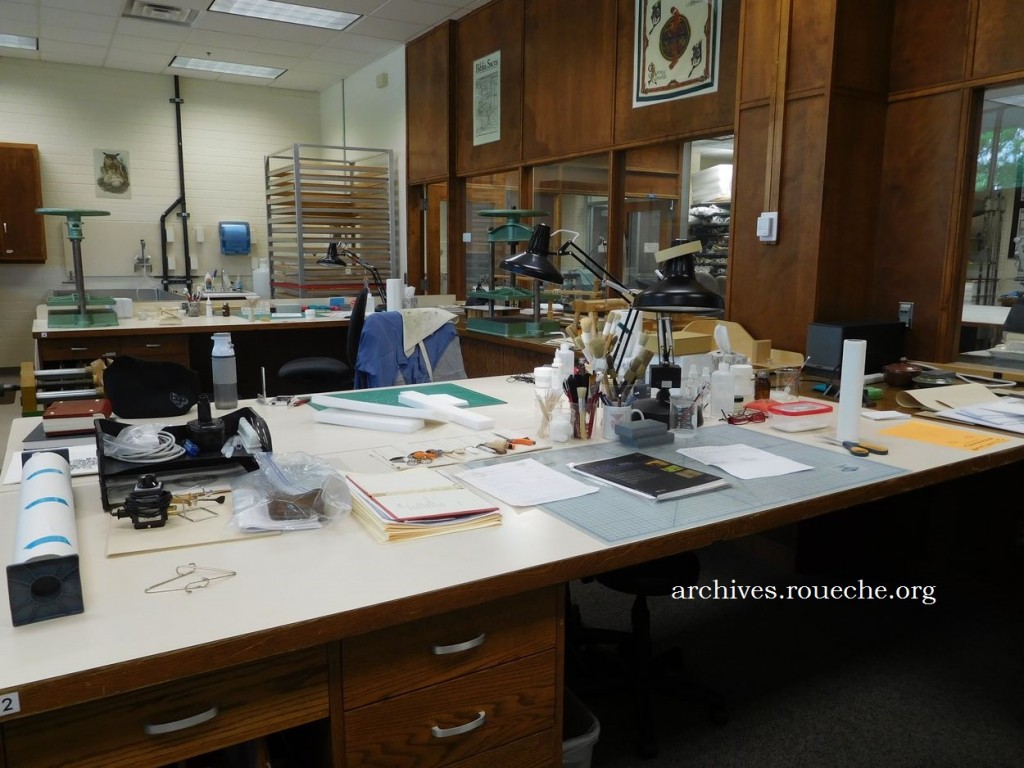

And a busy lab divided into individual work desks and surrounded by special project stations; like the humidifying hood.

As soon as one item is humidified, the student staffer transfers it to a press lined with blotters.

A weight is added so the humidified items will dry flat.

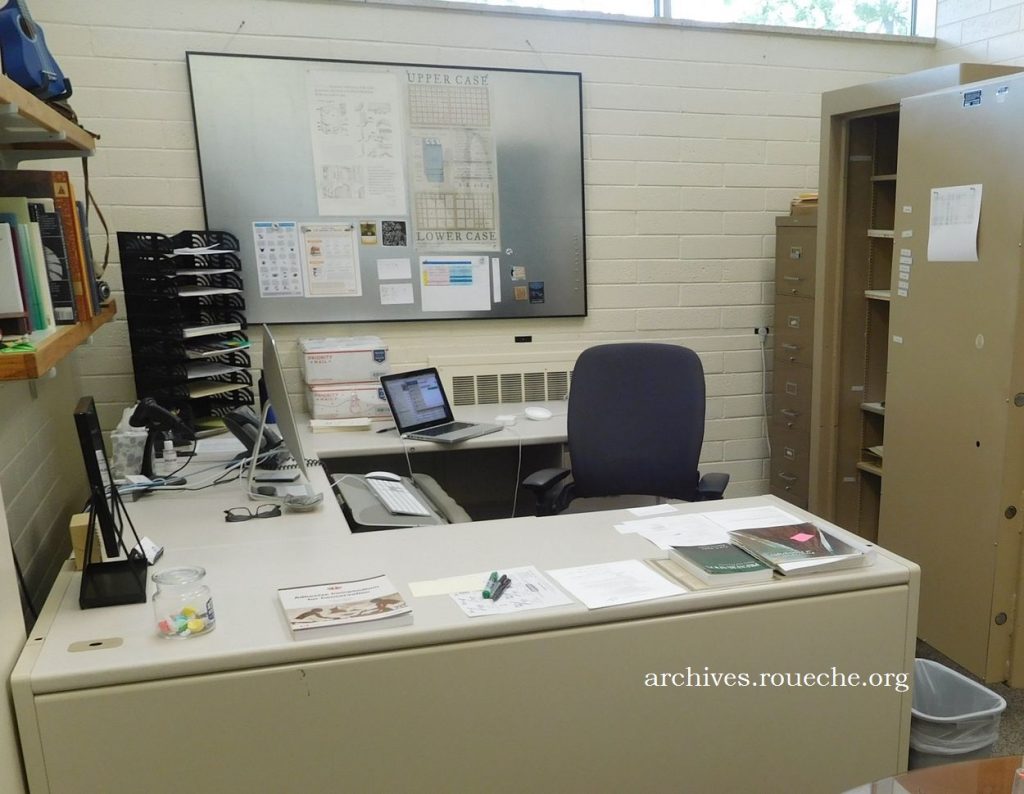

The two main spaces are flanked by smaller work rooms and offices.

There were a few other offices that I did not photograph. However, I had to take a picture of one of the book presses. I always find them fascinating.

Two interesting projects were in process during my visit. A student worker was planing the fore edge of a book receiving a re-built binding. This table vise has been modified with a plough for this step.

See the tiny strips falling to the floor? The conservator pushes the arm back and forth while shifting the blade ever so slowly across the surface of the pages.

There’s another view for you.

And there is a newly re-bound book all finished with a nice, level fore edge. I’d never seen anything like it, before.

But, the most interesting thing I saw during my visit was the magnetic wrapper that conservator Christina Thomas was creating for a rare, vellum bound volume. Chris explained that this process was developed by a University of Utah conservator, Tomomi Nakashima, as an alternative to building linen covered clam shell boxes.

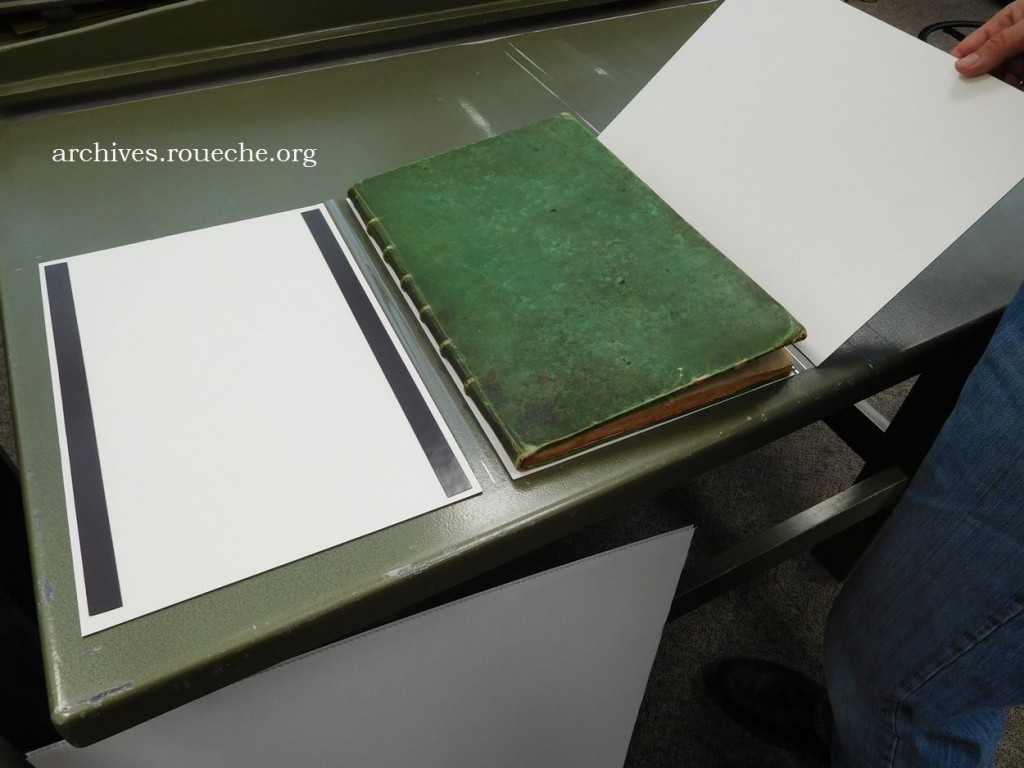

First, Christina measures and cuts 3 pieces of acrylic-coated mat board to the dimensions of the book cover. Then she lays them out on a piece of polyester film.

The film is trimmed to a length that allows it to be wrapped around the front cover of book and secured tightly. I’m simplifying things here, but basically, strips of adhesive are applied to one side of the boards. . .

The film is trimmed to a length that allows it to be wrapped around the front cover of book and secured tightly. I’m simplifying things here, but basically, strips of adhesive are applied to one side of the boards. . .

and magnetic strips are applied to the other.

and magnetic strips are applied to the other.

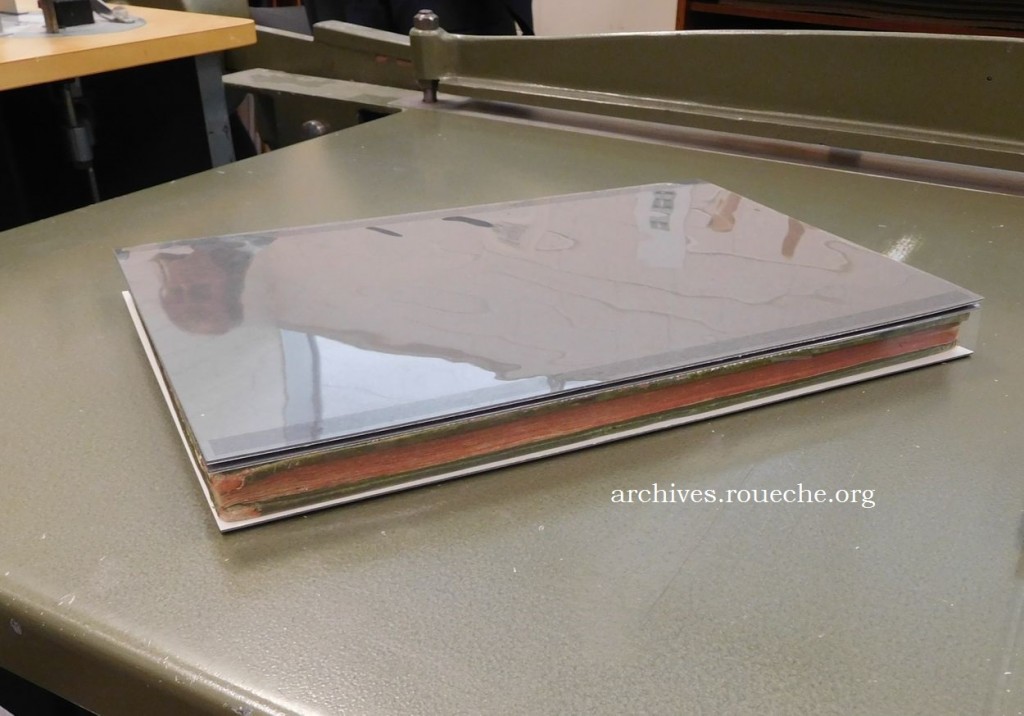

When the left and right boards are brought to the front, the magnetic strips hold them in place.

When the left and right boards are brought to the front, the magnetic strips hold them in place.

Isn’t that a beautiful thing? No adhesive or magnets are in contact with the book at anytime, AND, the conservator did not have to build a box, AND the wrapped book can now sit properly on a shelf.

Isn’t that a beautiful thing? No adhesive or magnets are in contact with the book at anytime, AND, the conservator did not have to build a box, AND the wrapped book can now sit properly on a shelf.

Christina has this procedure down to a science. She loves making them and I loved watching. I’m not saying I could make a magnetic wrapper (because I couldn’t) but I certainly appreciate the ingenuity that went into the design of it and the skill involved in its execution.

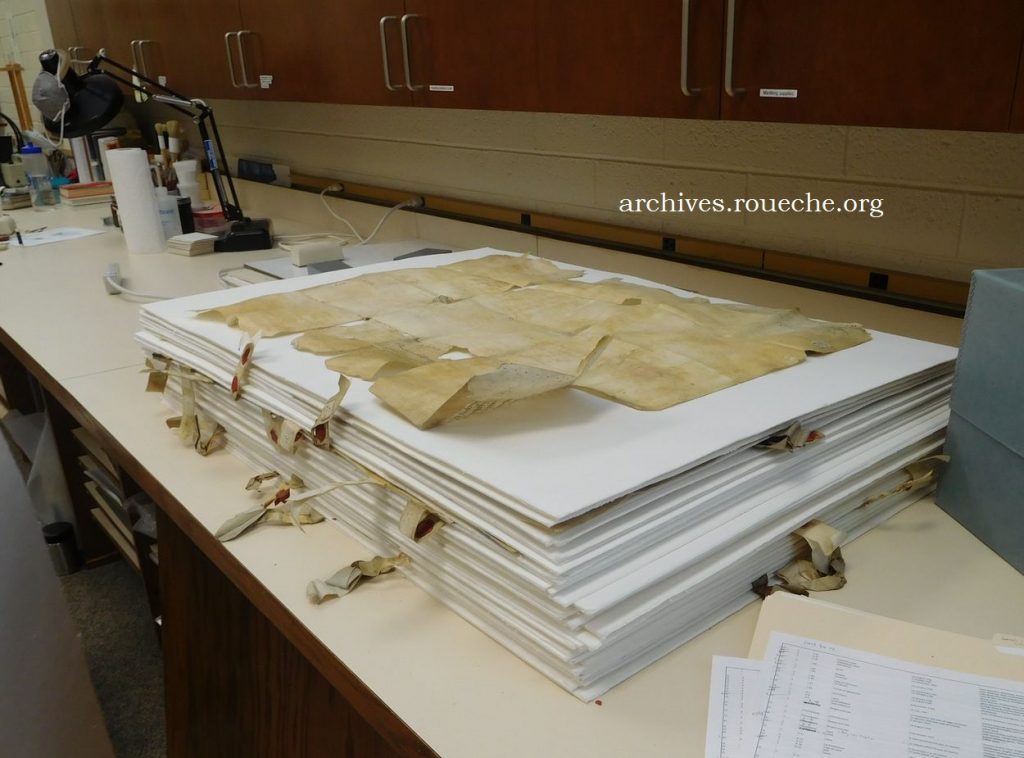

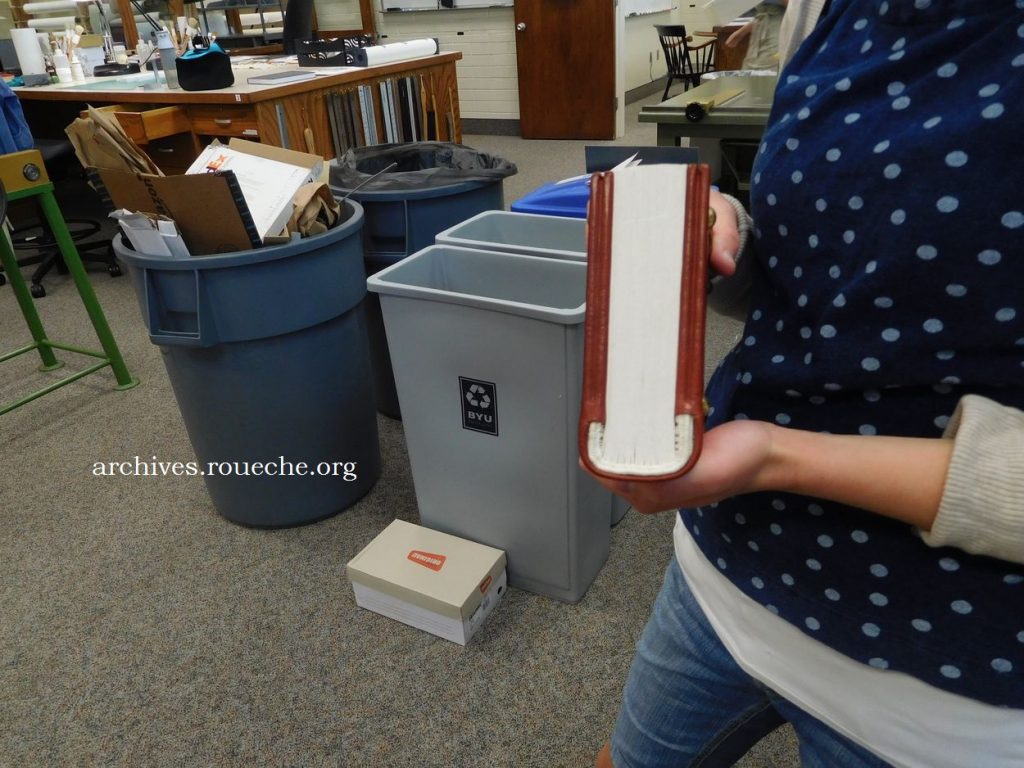

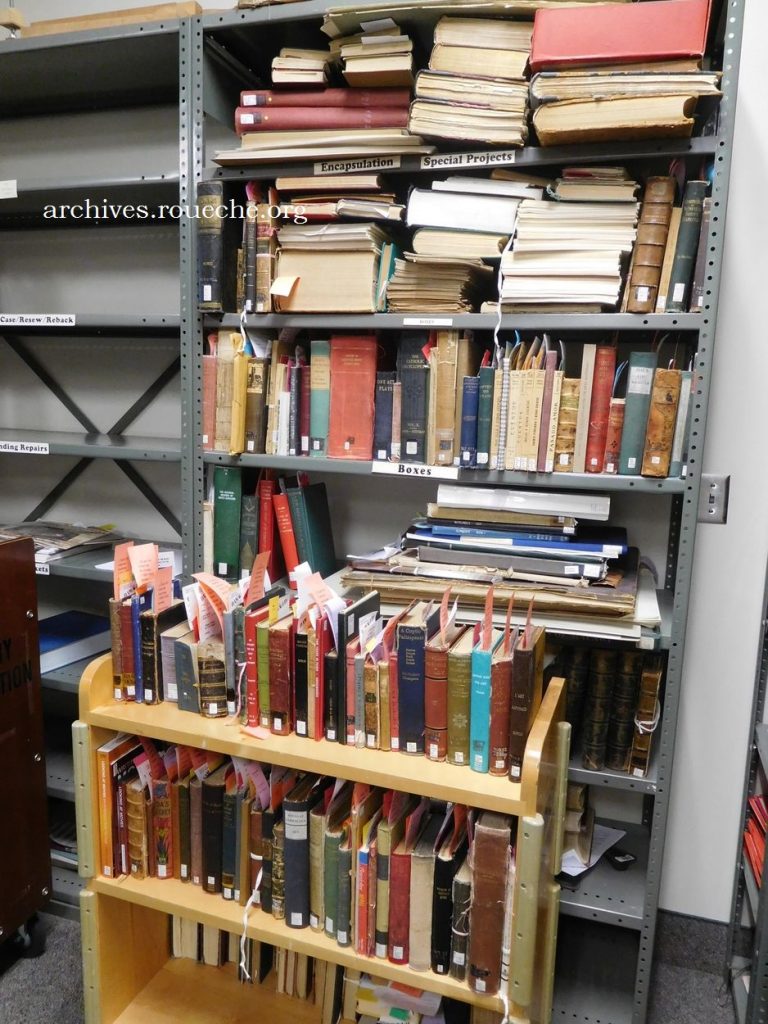

Next, we went across the hall and visited the book repair shop. This is where some of the HBLL’s 6,000,000 volume collection gets repaired.

This department is overseen by a full-time specialist and executed by a trained, part-time staff of students, for the most part. I wish I would have worked here during my college years instead of the football stadium. (But, I can make change faster than you can say “First down!”)

That concludes today’s tour. The next time you pass by a “Staff Only” sign at your nearby university library, you will have a better idea of what is going on behind closed doors to keep books in circulation and special collection manuscripts available for reference.

A big thank you to Christopher McAfee for taking time out of his work day to show me around. You’re the best, Chris, and please thank your staff for being so accommodating!

Feature image: An assortment of conservation brushes form a bridge between the two main work rooms.

3 Responses to Field Trip: BYU Book Conservation Lab